Case Studies Customer Testimonials — Measuring Outer Diameter

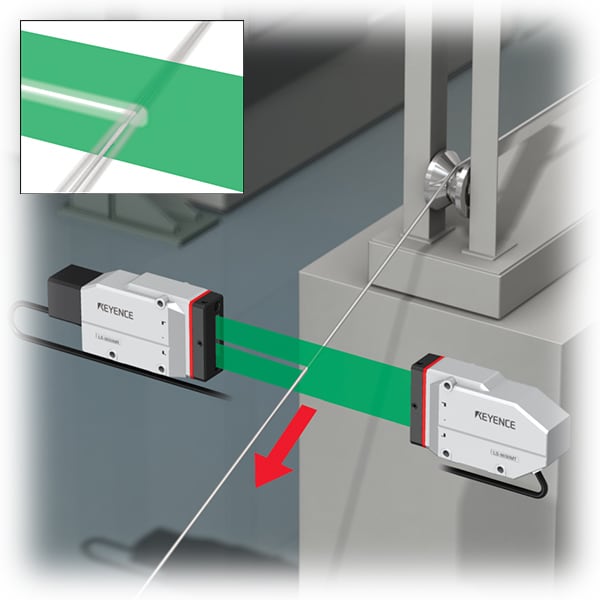

Case 1: Outer Diameter Measurement of Wires

| Industry | Transport/Metals Industry |

|---|---|

| Application | Outer Diameter Measurement of Wires |

| Model Adopted | LS-9000 Series |

Previously, We used laser micrometers to measure the outer diameter of wires. Our problem was that large measurement errors occurred whenever the wires shook, so we contacted KEYENCE.

They explained the cause of the errors, and helped us set up a test of the LS-9000 optical micrometer on our line. It was very successful, so we switched to it.

Customer

CustomerTestimonial

Thank you for using KEYENCE products.

One of the characteristics of the LS-9000 Series is its sampling rate, which is the fastest in its class at 16,000 samples per second. The high-speed exposure of the LS-9000 Series ensures that wires are identified clearly even when they shake, which enables highly precise measurements.

KEYENCE

KEYENCE

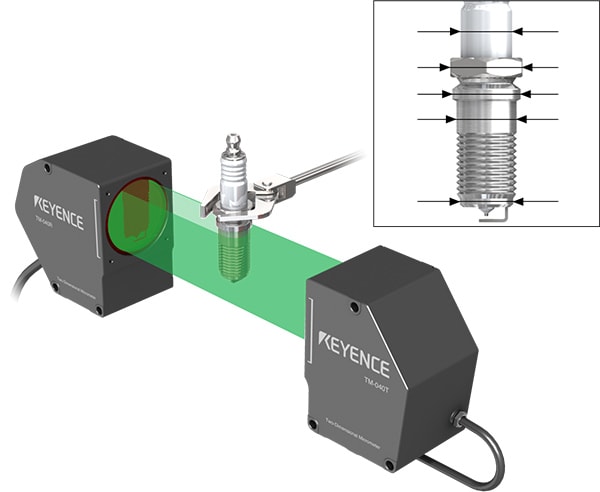

Case 2: Outer Diameter Measurement of Spark Plugs

| Industry | Transport/Metals Industry |

|---|---|

| Application | Outer Diameter Measurement of Spark Plugs |

| Model Adopted | TM-3000 Series |

Prior to sintering, the ceramics are soft, which means that they may be scratched by micrometers. In addition, there are many measurement points, so inspections took a long time.

The TM-3000 Series measures the outer diameters of multiple points at the same time in a non-contact manner, which was a big help.

Customer

CustomerTestimonial

Thank you for using KEYENCE products.

The TM-3000 Series can measure up to 16 points at the same time. Performing the measurements before sintering leads to increased yield and decreased costs.

KEYENCE

KEYENCE

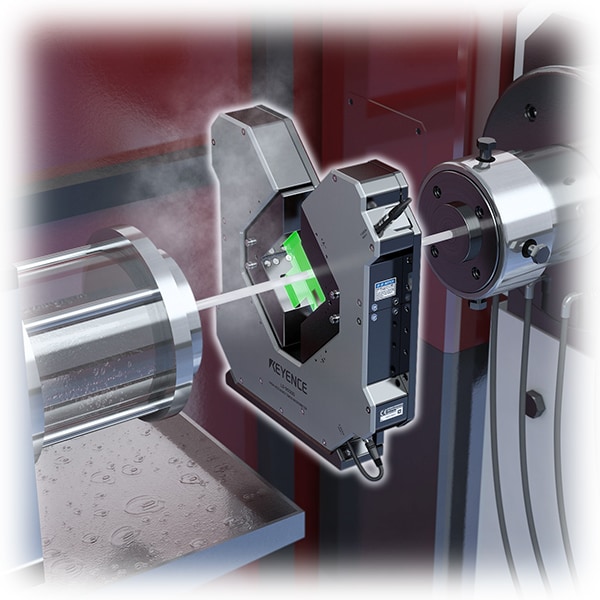

Case 3: Outer Diameter Measurement after Extrusion Forming

| Industry | Resin and Rubber Industry |

|---|---|

| Application | Outer Diameter Measurement after Extrusion Forming |

| Model Adopted | LS-9000 Series |

We were using micrometers to perform random inspections, but it's been a long term goal to perform 100% inspections. We've struggled to implement 100% inspections due to steam generation in the area creating a difficult environment, but after being introduced to the LS-9000, we decided to test it.

The LS-9000 was able to perform measurements without any problems even when left to run for a long period of time, so we installed it.

Customer

CustomerTestimonial

Thank you for using KEYENCE products.

The air purge can be used to enable stable measurements in poor environments such as those in which steam and dust are present. The LS-9000 Series is equipped with an air purge unit, which provides the LS-9000 Series with its environmentally resistant design.

KEYENCE

KEYENCE