Continuous Inkjet Printer

MK-G series

Continuous Inkjet Printer MK-G series

New

Simple.

Reliable.

Predictable.

Building a reliable inkjet printer has always been a top goal at KEYENCE. The newly developed MK-G Series furthers that goal with automatic processes that eliminate the need for user input, making it ideal for solving a wide variety of production site needs.

MK-G Series is the world's first self-troubleshooting continuous inkjet printer that completely eliminates the guesswork of inkjet maintenance and can be operated without... any specialised product knowledge or skills. By incorporating KEYENCE sensor technologies to enhance self-diagnostic capabilities, the new MK-G Series can automatically perform maintenance and troubleshooting on its own – just like how a trained inkjet technician would. The unit features new functions that ensure automatic cleaning is performed every time before shutdown even when the power is disrupted, and allow users to check the status and perform operations on the printer remotely from a PC or Smartphone.

Applications

-

Plastic bottles

-

Glass containers

-

Pipes

-

Paper tubes

Features

Hands-free Cleaning [Auto-shower Cleaning]

The auto-shower cleaning function of the MK-G Series cleans not only the ink path but also all components necessary for maintaining print quality. Suction during cleaning also helps to reduce odors. After cleaning is complete, the built-in blower automatically dries the head.

Conventional head cleaning

Manual cleaning was required to wash residual ink off the inside of the head.

Auto-shower cleaning

In addition to cleaning the ink paths, the key parts of the head are also subject to high-pressure cleaning. This negates the need for manual cleaning.

Self-diagnosis Followed by Automatic Cleaning When Necessary

MK-G enables self-diagnosis and cleaning to ensure stable startup.

Smart Startup

To start the MK-G Series, simply press the Smart Startup button. The printer will automatically obtain the device status and select the necessary cleaning method. Cleaning is performed only when required and the minimum amount of solvent is used, significantly reducing running costs.

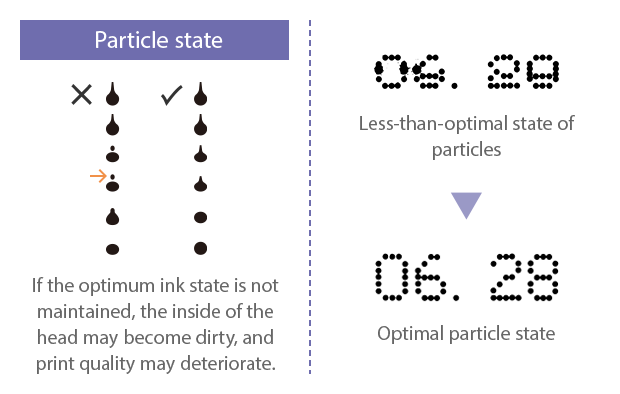

Eliminate Temperature-based Printing Problems

Automatic Ink Particle Optimization

The surrounding environment, temperature, and ink viscosity all have an effect on the condition of ink particles and their suitability for printing. The MK-G Series senses the ink particles 10 times per second, which enables automatic adjustment to ensure the best conditions. This allows the device to provide superior printing at all times, regardless of the environment.