Elemental Analyzer

Solve a wide range of applications - from imaging to elemental analysis - with a single device. By eliminating the need for a vacuum, conductivity treatment, cutting, or other pre-processing procedures, the EA Series simplifies material identification and allows any user to instantly obtain results.

Products Lineup

Introducing an elemental analyzer head for use with VHX Series microscope. Simply place the target on the stage to analyse with no destructive sample preparation, deposition, or vacuum required. AI-based suggestions also make it possible for anyone to identify substances through elemental analysis.

Features

Identify Substances Directly from Your Microscope

Place-and-Analyse Operation

One-click elemental analysis is possible.

Users can easily go from magnified observation to elemental analysis without needing to re-align or focus the laser objective lens.

No Pre-Processing or Vacuum Required

Non-destructive, alteration-free analysis is possible on targets of any size.

No conductivity treatment or vacuuming is required for analysis.

Automatically Identify Materials

The detected elements are analysed.

The most likely material is instantly suggested.

An integrated AI function will recommend the most likely detected material.

The database can also be used to collect historical in-house analysis results for reference when similar foreign particles are detected.

Elemental analysis (EA) refers to detecting the compositional elements of the target and determining how much of each element there is. Elemental analysis is broadly grouped into organic analysis—in which organic compounds are analysed in fields such as pharmaceuticals and biotechnology—and inorganic analysis—in which the composition and impurities of industrial materials are analysed.

Organic Analysis

When the organic compound subjected to analysis is a mixture, analysis is performed via purification. For example, the solubility in a solvent is investigated or the purity is investigated by isolating the targeted component via distillation and then physical properties such as melting point, boiling point, and spectrum are measured. In this manner, the molecular formula is determined by subjecting the compositional elements to qualitative and quantitative analyses and measuring their molecular weights. Organic analysis is useful in the functional expression of cutting-edge materials in fields such as pharmaceuticals, biotechnology and electronics.

Inorganic Analysis

Because inorganic analysis can be applied to all materials handled in inorganic chemistry, the types of elements and their number are far greater than organic materials. Hence, inorganic analysis is widely used in industrial fields where diverse materials and components are handled. Inorganic qualitative analysis is the method used to determine the types of components such as atomic species, groups of atoms, molecular species and isotopes within inorganic materials. This analysis is performed qualitatively or via detection. The analysis method used to determine the amount of contained components is called inorganic quantitative analysis. Quantitative analysis is used in a variety of industries for chemical analysis of industrial materials, direct analysis of solid samples, microanalysis of pharmaceuticals and biological samples, analysis of ion components in electronics fields such as semiconductors and fields such as secondary batteries.

Types of Elemental Analysis (Inorganic Materials)

This section introduces typical inorganic analysis techniques and principles of analysis equipment.

ICP-MS (Inductively Coupled Plasma Mass Spectrometry)

Also known as inductively coupled plasma mass analysis, this mass analysis method uses argon plasma for ionisation. With this method most elements can be ionised at a rate of 90% or higher. First, the sample solution is converted into an aerosol and inserted into the plasma. The elements within the sample solution dissolve, vaporise, atomise and are ionised. Then, they pass the sampling interface and are drawn into the mass analysis section which is subject to a high vacuum. These elements are focused by an ion lens, separated by a mass spectrometer and measured by a detector.

ICP-AES: Inductively Coupled Plasma Atomic Emission Spectroscopy

This form of atomic emission spectroscopy uses high-frequency inductively coupled plasma (ICP) as its light source. The sample solution is converted into an aerosol and inserted into high-temperature argon plasma for measurement. Spectroscopy of the light emitted when an element returns to its ground state provides a qualitative analysis of the element from the wavelength of the light and a quantitative analysis of the element from the intensity of the light. Many types of elements can be measured, and this method is used in the composition analysis that identifies the metallic elements in thin films. Analysis equipment is available in sequential types, which measure a single element with high resolution, and multi-channel types, which use multiple CCDs to simultaneously measure multiple elements.

AAS: Atomic Absorption Spectrometry

This method uses a graphite kiln for converting the sample into a solution or atomisation within the frame to heat the measurement sample and atomise its elements (atom vaporisation). The element to measure is then permeated with light at an appropriate wavelength. The atoms at their ground state absorb this light and are excited. The element concentration is measured according to the amount of light absorbed by the element under measurement. Because a dilute acid aqueous solution is used for the measurement sample, solid samples must undergo appropriate pre-processing.

XRF: X-Ray Fluorescence Spectrometry

In this analysis method, the sample is irradiated with X-rays (primary X-rays). Then, the excited fluorescent X-rays (secondary X-rays) are detected to qualitatively and quantitatively measure the element. When the sample is subjected to X-rays, the inner shell electrons jump out to the outer shell, creating vacancies. The element is measured from its characteristic fluorescent X-ray which is generated from the energy difference when electrons move to fill these vacancies. Different methods are used depending on the element to measure. Wavelength-dispersive X-ray fluorescence spectroscopy (WDX) separates and detects the fluorescent X-rays with crystals and energy-dispersive X-ray fluorescence spectroscopy (EDX) detects the fluorescent X-rays with a semiconductor detector.

LA-ICP-MS: Laser Ablation Inductively Coupled Plasma Mass Spectrometry

In this method, the surface of a solid sample is exposed to concentrated laser light which evaporates and micronises the sample. The sample is then inserted into plasma via carrier gas for analysis and ionisation. Measuring these ions with a mass spectrometer makes it possible to investigate the elements of the localised parts of the sample.

Capillary Electrophoresis (CE)—which qualitatively and quantitatively investigates inorganic ions as well as organic acids and amines with low molecular weight in aqueous solutions, and Ion Chromatography—which measures acids and bases in solid samples with water extracted and gaseous samples with solutions collected, are also available.

Elemental Analysis (Inorganic Materials) via LIBS

The analysis methods introduced above all require significant pre-processing that are time-consuming and require a skilled user to perform. LIBS analysis significantly simplifies the identification of inorganic materials by eliminating the need for pre-processing (vacuum, cross-sectioning, etc.). Information such as the analysis principle, characteristics, types and applications of this method are explained below.

What Is LIBS Analysis?

Laser Induced Breakdown Spectroscopy (LIBS) is a type of inorganic analysis that uses the light emission analysis method. A short-pulse laser with high energy density is projected onto the surface of the sample, converting a small piece of the sample to plasma which is sampled, atomised, and excited. When the part exposed to the laser returns to its ground state, light is emitted. Measuring the wavelength and intensity of this light with a spectrometer or CMOS provides data that allows for the qualitative and quantitative analysis of the elements contained in the sample.

LIBS Analysis Characteristics, Applications and Equipment Types

In LIBS analysis, there is no need for processes that use distillation, atomisation, a vacuum, carrier gas, etc. to insert the sample into the detector. Because there is no need to modify solid samples before starting their inorganic analysis, elemental analysis is possible with far less hassle, time and expertise compared to other analysis methods. It is also possible to consolidate the analysis equipment into a small package that can fit in any lab space. This equipment is also used in the inline selection of raw materials. For purposes such as research and development, acceptance inspections of materials and quality management and quality control in manufacturing processes, digital microscopes and LIBS analysis equipment are generally used together for observation, analysis and elemental analysis, allowing the status and composition of the target to be checked from its outer appearance. The digital microscope and LIBS analysis equipment being integrated into a single device allows for seamless execution of observation, analysis and elemental analysis, dramatically improving work efficiency.

Benefits of KEYENCE's Elemental Analyzer

Elemental analysis via LIBS analysis can be carried out seamlessly with a single KEYENCE Digital Microscope while performing observation on the target sample.

Attaching the EA-300 Series laser-based elemental analyzer, which is capable of high-speed LIBS analysis, to KEYENCE’s VHX Series Digital Microscope provides three optical systems: an observation optical system, a laser optical system, and a spectroscopic optical system. This one device provides not only high-resolution observation and accurate measurement and analysis, but also elemental analysis via LIBS. Conventional elemental analysis required that the sample be observed with a microscope, pre-processed, and then analysed with highly specialised equipment.

The VHX Series objective lens and laser-based elemental analyzer use the same field of view, so when a foreign particle or material needs to be identified there is no need to search for the area of interest or re-align focus.

With conventional systems having separate observation and analysis equipment, it is difficult to match the observation location and the location used for elemental analysis, leading to time-consuming adjustments and inaccurate results. Because it is now possible to instantly perform elemental analysis at the intended position, the misalignment that occurred with conventional systems is now a thing of the past.

Normally, determining the element or material from the detected information requires expertise. However, with the laser-based elemental analyzer, the AI-suggest function identifies the included elements and materials from the obtained elemental pattern, instantly displaying the element names and their percentages as well as the material name.

The EA-300 Series has an integrated database including thousands of elemental patterns. The AI uses this extensive database to instantly suggest not only the detected element, but the material name as well. Material data is organised hierarchically to make it easy to check the generic name, specific name, and description. The database can also be used to collect historical in-house analysis results for reference when similar foreign particles are detected. This makes it possible even for people with no advanced technical skills to instantly identify the material of the analysis target.

Elemental Analyzer Case Studies

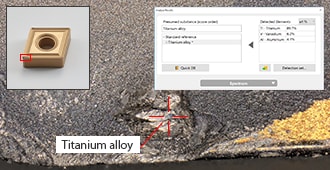

Automotive/Metals: Identifying Foreign Particles Embedded in a Cutting Tool

Cutting tool (200×)

The EA-300 Series laser-based elemental analyzer can perform magnified observation of a cutting tool attached to a cutting machine and identify the defective area as well as the embedded metal. Linked with the observation field of view, elemental analysis (LIBS analysis) of a single point could be executed, and the elements detected from the embedded metal were titanium (Ti), vanadium (V), and aluminium (Al), indicating that the embedded metal was a Ti-Al-V alloy. It is possible to instantly determine whether the detected material is part of the processed target or from a different machine somewhere in the process. The ability to quickly identify the cause of the defect significantly reduces the time spent on establishing countermeasures.

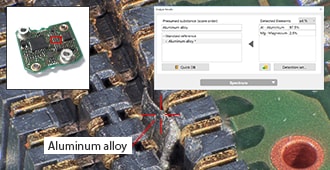

Electrical/Electronic Devices: Identification of Foreign Particles on a Connector

PCB connector (50×)

Foreign particles affixing to a connector not only leads to product defects and malfunctions, but can even lead to the loss of entire PC boards because of damage to the contacts of onboard parts due to fit defects. In this example, the foreign particle identified with magnified observation (50×) was subjected to high-speed LIBS analysis resulting in the detection of aluminium (Al) and magnesium (Mg), indicating that the foreign particle was an Al-Mg alloy. It was quickly determined that the material was not caused by the product itself, which made it possible to review the environment where the manufacturing process is carried out and the equipment used in this process. Even if foreign particles exist in multiple locations, elemental analysis can be applied to all of them at the same time, allowing for efficient identification of the causes of defects and leading to immediate solutions.

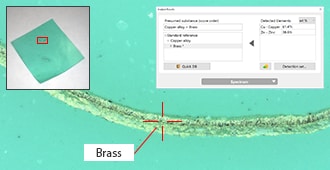

Chemicals/Raw Materials: Identification of Foreign Particles in a Multi-layer Film

Multi-layer film (100×)

After using magnified observation (100×) to confirm the presence of foreign particles in a multi-layer film, elemental analysis was performed with the EA-300 Series laser-based elemental analyzer, detecting copper (Cu) and zinc (Zn), indicating brass. This immediate identification of the material of the foreign particle quickly provided the basis of the determination of how the foreign particle ended up in the film, helping to identify which processes needed to be improved and significantly reducing the time spent on establishing countermeasures.

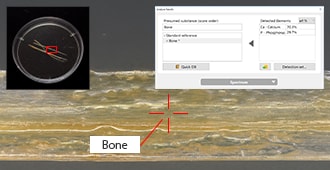

Food/Pharmaceuticals: Identification of Foreign Particles Mixed in Food

Foreign particles in food (200×)

The mixing of foreign particles in products is a major problem related to safety and reliability in the manufacturing of food and pharmaceuticals. In this example, a foreign particle in a piece of food was identified with magnified observation (200×) and was then subjected to LIBS analysis which detected calcium (Ca) and phosphorous (P), pointing to bone as the contaminant. Conventional models using microscopes can only hypothesise on the basis of the colour and shape of the particle, and the actual analysis had to be entrusted to a different department or even outsourced, so it took a long time to determine the material. With the EA-300 Series, it is possible to instantly identify the elements and material of the foreign particle at the same time as its outer appearance is checked, allowing for thorough quality assurance and dramatically faster process improvement.

Frequently Asked Questions About Elemental Analyzers

KEYENCE products can not only measure and analyse contaminants, but can also subject them to elemental analysis. The VHX Series Digital Microscope, to which the EA-300 Series laser-based elemental analyzer can be attached, can use its automatic area measurement/count function to carry out contaminant measurement and analysis compliant with the ISO 16232/VDA 19 international industrial standard for cleanliness inspection. Furthermore, after minute particles are detected, elemental analysis (LIBS analysis) can be performed directly on any residual foreign particles. In addition to contaminant measurement and analysis, this one unit can perform all the work required for elemental analysis and material identification, eliminating the need to move the sample between instruments. Furthermore, the interlocking of the field of view and focus means there is no risk of losing sight of the target particles.

Yes, it can. The VHX Series Digital Microscope provides a free-angle observation system and a highly accurate XYZ-axis motorized stage, which allow for adjustment along three axes—field of view, rotation axis, and oblique axis—and prevent the field of view from shifting even when the head is at an angle. The result is tilted observation that is highly flexible, accurate, and can be used with targets having a wide variety of shapes. Attaching the EA-300 Series laser-based elemental analyzer to this observation system allows for easy capturing of recessed locations that cannot be viewed without tilting the head.

No. The EA-300 Series laser-based elemental analyzer can perform elemental analysis for multiple locations in the field of view at the same time. Using this multi-point analysis function and selecting multiple locations improves analysis efficiency when, for example, analysing the elements of a base material and foreign particles at the same time, or if several foreign particles are adhering to the same target.

No. Elemental analysis with no pre-processing can be carried out even for targets with coatings, films or plating. With the multi-layer analysis function, the target can be drilled via continuous laser irradiation, allowing for analysis of not just the top surface, but also the subsequent layers with no pre-processing required.