Flow Sensors / Flow Meters

Products Lineup : Liquid Flow Rate

The FD-H Series clamp-on flow sensor is easily installed, without any pipe modification, by simply clamping to the outside of a pipe, tube or hose. This series provides stable flow rate measurement regardless of the pipe or liquid. In addition to metal and hard plastic piping, hoses (including high-pressure hoses) can also be supported. This product can not only measure the flow rates of various liquids such as water, DI water, oil, chemicals, and coolants but can also tolerate bubbles, high temperatures, and highly viscous liquids. Connecting a concentration sensor and temperature sensor allows for the centralised management of multiple parameters, helping improve product quality, and decrease costs.

Features

Countless Opportunities for Process/Machine Improvement

Supports Any Pipe, Type of Liquid, and Liquid Condition

KEYENCE clamp-on flow sensors perform detection from outside the pipe for a wide variety of applications. Now it is possible to monitor liquids with bubbles, high temperatures, and high viscosities.

- 2x

- 1.75x

- 1.5x

- 1.25x

- 1x, selected

- 0.75x

- 0.5x

- Chapters

- descriptions off, selected

- captions settings, opens captions settings dialog

- captions off, selected

This is a modal window.

Beginning of dialog window. Escape will cancel and close the window.

End of dialog window.

This is a modal window. This modal can be closed by pressing the Escape key or activating the close button.

Unmatched Features

A detachable display allows for remote monitoring while also clearly displaying current values, real-time graphs, historical data and more. Universal connectivity is achieved with a choice of control outputs, analogue outputs, and IO-Link. Additional features include high environmental ratings (IP65 & IP67), a built-in diagnostic function, and accuracy of 3% of R.D.

Extend Beyond Flow Sensing to Understand the Full System

Connecting other sensors to the FD-H Series allows for the continual recording and management of multiple parameters including liquid flow rate, concentration and temperature.

- 2x

- 1.75x

- 1.5x

- 1.25x

- 1x, selected

- 0.75x

- 0.5x

- Chapters

- descriptions off, selected

- captions settings, opens captions settings dialog

- captions off, selected

This is a modal window.

Beginning of dialog window. Escape will cancel and close the window.

End of dialog window.

This is a modal window. This modal can be closed by pressing the Escape key or activating the close button.

Products Lineup : Gas Flow Rate

The compact case of the FD-EP Series houses a flow sensor and a pressure sensor, making it easy to diagnose the status of pneumatic equipment. The specialised application function makes real-time diagnosis and predictive maintenance of cylinders, suction transfer, seating and air blowers easy. The free flowing structure prevents pressure loss, clogging and supports both small and large flows. When selecting the sensor, just choose the one that matches your tube diameter. The high-definition display allows for intuitive operation with no need for an instruction manual. This one device can handle applications in which gases flow forward and backward such as cylinder forward and backward motion and the suctioning and vacuum release during suction transferring.

Features

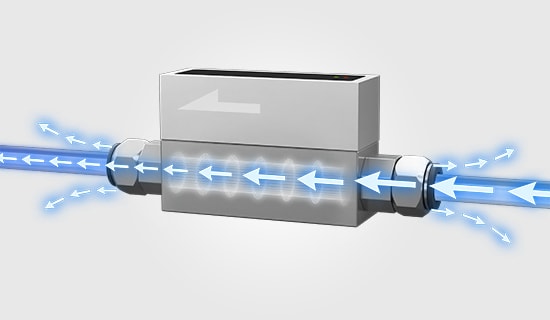

Zero Risk of Clogging

The FD-EP Series has a free flowing structure with no protrusions or obstructions in the flow path. Therefore, there is no need to worry about clogging or pressure loss caused by the flow sensor itself. Enjoy peace of mind throughout the installation process.

Conventional Unit

Pressure loss and clogging caused due to rectifier mesh plate inside.

FD-EP Series

Free flowing structure

There are no protrusions or obstructions that can cause pressure loss or clogging.

Selection Is Easy

Conventional air flow sensors have a different rated flow range depending on the model, even for the same tube diameter, making it very difficult to find the appropriate model for novel applications. The FD-EP Series can handle flows ranging from minute to large, eliminating the need to worry about the rated flow. Choosing a product is as easy as selecting the tube diameter.

Comparison of rated flow ranges (example with ø8 tube and fluid pressure of 0.4 MPa)

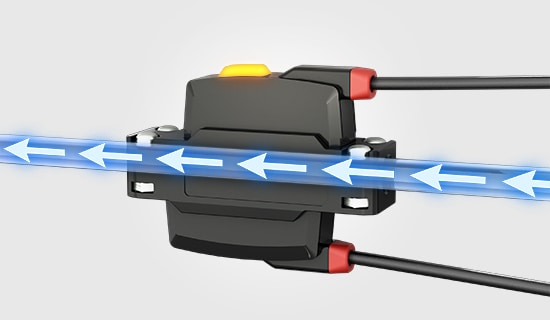

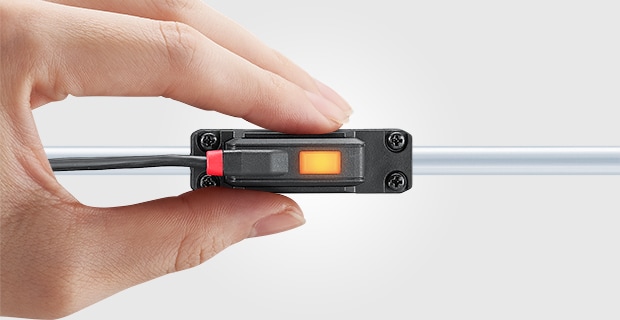

The FD-EC Series easily attaches to the outside of a tube, eliminating problems such as pressure loss and clogging, allowing for an uninterrupted supply of air. It can measure small and large flows and is compatible with various tube materials. When selecting the sensor, just choose the one that matches your tube diameter. The high-definition display allows for intuitive operation via the display amplifier, and diagnostic mode makes it possible to check the status while the sensor is attached to the tube. This sensor can detect gases regardless of the direction they flow, allowing for installations that fit the existing device layout.

Features

Zero Installation Risk

The FD-EC Series is free from all risks associated with conventional flow sensor installation, such as pressure loss, clogging, air leakage, or contamination. Also, because there is no need to cut tubes, the air supply does not need to be temporarily shut off during installation.

Conventional Unit

- Clogs due to multi-layer mesh structure

- Leaks from coupling

FD-EC Series

- Zero risk of pressure loss, clogging or contamination

- Zero air leakage

Ultra-Compact and Ultra-Lightweight

Air tubes are often thin, with limited space between tubes. The FD-EC Series is ultra-compact and clamps on for easy installation anywhere. The ultra-lightweight body also eliminates the need for mounting brackets.

High-density mounting is possible.

Products Lineup : Air Efficiency Module

MP-F Series simultaneously senses the flow, pressure, temperature and humidity of air. This can all be visualized along with energy consumption when the connected power monitor is used. This unit is equipped with a function that automatically records the air and electricity consumption (data that is vital when attempting to reduce energy consumption) at all times. The stored data can then be checked on the highly expressive multi display. Also, data can be analysed easily with the specialised PC software. The shut-off valve is an energy-saving feature that eliminates unnecessary air consumption by blocking air when the machine is not operating. This unit monitors the air status to detect problems such as pressure drops and condensation before they occur and notify the user of these errors.

Features

Visualise Air and Electricity Consumption

Easily visualise equipment energy consumption (air and electricity consumption*), which is important for energy conservation measures. The unit also has a “full-time recording function” that automatically records data on the main unit. Accumulated data can be viewed on an expressive multi-display.

*An energy monitor (MP-FEA1) and CT (MP-FEC) are required to measure electricity consumption

Flow × Pressure × Temperature × Humidity + Energy

The MP-F Series enables equipment energy consumption (air and electricity consumption) to be easily visualised, which is important for energy conservation measures. While doing this, the single unit can monitor air pressure, temperature, and humidity. Additionally, it comes with a shutoff valve that conserves energy by shutting off air leaks that can occur when the equipment is not in operation.

-

1Flow

-

2Pressure

-

3Temperature

-

4Humidity

Flow meters, also known as flow sensors, are used to measure the flow rate of a liquid or gas. There are a variety of different types of flow meters, including ultrasonic, electromagnetic, Karman vortex, paddlewheel, floating element, thermal, and differential pressure types. Flow meters that require no moving parts in contact with the target liquid are particularly effective in avoiding potential problems. For example, ultrasonic meters—also known as clamp-on systems—can be installed from outside the pipe for completely non-wetted measurement, preventing any risk of adverse effects on the liquid and eliminating the need for piping work. Electromagnetic meters detect flow via electromotive force created through electromagnetic induction. Models that use an electrode outside the water outlet are most effective. Meters that use the Coriolis method measure the backward force created by the flow of liquid through an oscillating U-shaped pipe. Alternatively, thermal meters measure the flow rate by looking at the amount of heat the liquid removes from a heating element.

Benefits of Flow Sensors / Flow Meters

The manufacturing of products can involve a wide variety of liquids. To ensure quality control, the liquid is monitored using a flow meter and then managed/analyzed accordingly to improve or stabilise product quality. Understanding the different types of flow meters plays an important role in performing sufficient fluid management and analysis.

Using a flow meter for managing liquid flow enables data acquisition for alarms, diagnosis, and analysis. It also allows for management of minute flow rates such as equipment discharge and spray volumes, and management of air, nitrogen, or argon gas supplies based on instantaneous and total flow rates. Flow meters equipped with an analog output can respond flexibly to control and manage needs by transmitting alarm output and diagnostic/analysis data to a PLC or PC. Clamp-on flow meters, which use non-wetted methods that do not adversely affect the liquid, are also capable of measuring very low flow rates at high speeds. This is often necessary for controlling release agent, disinfectant alcohol, and flux application amounts. Mass flow sensors are not easily affected by temperature or pressure, making them suitable for the management of gases.

Flow control using a flow meter enables both predictive maintenance and superior device protection, such as when an optimum temperature range is specified or a correct amount must be used for cooling water circulation. Flow control makes it possible to prevent any deterioration in quality or malfunctions with equipment due to improper cooling.

Quick detection of a decrease in flow rate makes it possible to immediately perform predictive maintenance to avoid adverse effects on production or equipment. This means flow control using a flow meter is essential. A flow meter with two outputs enables the output of both a predictive alarm and the main alarm for proper maintenance before jigs or equipment becomes damaged. Monitoring the conditions of filters and strainers is also important for detecting clogs that may reduce flow. In other cases, bent or clogged pipes may not show a change in pressure, only a decrease in the flow rate. Using a flow meter in addition to a pressure sensor makes it possible to detect problems in the piping quickly for immediate response.

Manufacturing sites often use argon gas for welding, nitrogen gas for oxidation-prevention and heat treatment, and various other resources such as hydraulic oil and coolant. Using a flow meter for flow control makes it possible to visualize the amounts of resources used and to conserve energy (which reduces costs).

Flow meters capable of managing instantaneous and total flow rates simultaneously can detect abnormal flows. These devices can also gather data to determine possible reductions in the consumption amounts based on per-hour usage. Also, if the flow meter has no moving internal components, reductions in pressure due to clogging or other problems can be eliminated, contributing to greater energy conservation with no unnecessary load on pumps. Clamp-on flow meters can also be installed without having to cut piping, eliminating the risk of liquid and air leakages due to added pipe seams.

Flow Sensor / Flow Meter Case Studies

Equipment requiring liquid management (coolant, cleaning fluid)

Equipment requiring liquid management and flow monitoring include injection moulding machines (mould coolant flow control), die-casting machines (coolant and mould release agent flow control), grinding machines and cutting machines (coolant flow control), sputtering systems (coolant flow control), and spot welding machines (coolant flow control). Using an applicable flow meter or flow sensor for flow management stabilises product quality and prevents potential problems with equipment.

Equipment requiring liquid management (oil, coating solutions, chemical solutions, etc.)

Because liquid flow rates and process management are closely intertwined, flow meters and flow sensors are also useful in controlling the flow of liquids other than coolant and cleaning fluid. For example, flow control is also necessary with high-frequency quenching equipment (quenching fluid flow control), lapping/polishing/CMP equipment (slurry), dispensing equipment (flux, hot-melt, ink, grease, adhesives, painting solutions, coating agents, resist solutions, mould release agents, etc.), precision presses (lubricant, etc.), two-component mixers (pre- and post-curing agent liquids, water, printing paint, chemicals, emulsions, adhesives, etc.), cutting machines (for checking cutting oil amounts, etc.), concrete mixers and manufacturing equipment (water volume being mixed with materials), and flue gas neutralisation equipment (water and chemical solutions used during smoke evacuation).

Equipment requiring gas flow control (nitrogen, oxygen, air, etc.)

Flow meters and flow sensors are used in processes and machines requiring the flow control of gases such as nitrogen, oxygen, and air. This includes reflow furnaces (nitrogen (N2) flow control to prevent oxidation), quenching furnaces (nitrogen (N2) supply control to prevent oxidation), chip component conveyors (for checking airflow during chip component absorption), electronic component packages (management of enclosed gas (nitrogen) to prevent oxidation), ionizers (air purge flow control), and painting robots (paint (liquid) and air (gas) management).

Frequently Asked Questions About Flow Sensors / Flow Meters

Air bubbles can enter the pipe with the liquid or be formed in the pipe due to impurities or other factors. Bubbles can cause Karman vortices to occur in vortex flow meters, and ultrasonic wave propagation can be obstructed in conventional ultrasonic flow meters, causing the flow meter to malfunction. Generally speaking, flow rates can be measured with no effects from air bubbles when using a meter that measures using the Coriolis method. In recent years, ultrasonic wave flow meters have also begun using stronger ultrasonic signals to ensure adequate signal propagation, even if bubbles are generated. Some ultrasonic flow meters are also able to cancel out the effects of air bubbles or to generate an alarm if air bubbles are detected.

For flow meters that use a standard wetted electrode, insulating deposits inside the pipe can make measurement impossible. Conventional electromagnetic flow meters are also prone to such problems. Flow meters that use capacitive detection with electrodes on the outside of the pipe are effective at preventing these kinds of adverse effects. Fully penetrating electromagnetic flow meters detect liquid from outside the pipe, allowing for stable detection even if the pipe is covered with insulating deposits. Naturally, badly contaminated pipes will require cleaning or other maintenance because of the potential adverse effects on the equipment.

The effects of frequent bending, branching, or diameter variations can result in an uneven velocity of flow in the liquid. This may result in significant measurement errors. To ensure a uniform velocity distribution, a straight section of a sufficient length must be provided on the upstream side of the flow meter or flow sensor. This straight section should be at least 5 times longer than the diameter of the flow path, or 20 times longer if severe deflections or swirling currents exist. If significant measurement errors still exist, consider installing a valve or aperture.

As liquid flows through piping, valves are opened/closed and as connected pumps and other equipment operate, vibrations can be generated. Such vibrations and other noise can result in measurement errors. Karman vortex-type and Coriolis-method devices are often affected by vibrations and are likely to suffer from incorrect measurements. Electromagnetic and ultrasonic devices, however, are virtually unaffected by vibrations. In particular, ultrasonic flow meters that are capable of transmitting and receiving ultrasonic waves at high frequencies are less susceptible to vibrations and noise to ensure stable flow measurement.