Laser Sensors

A rich lineup of remote setup and received light intensity differentiation laser sensors. This page introduces compact digital CMOS laser sensors that have a built-in amplifier and boast high durability and stability, reflective/thrubeam model laser displacement sensors that are easy to use and have the versatility to support diverse applications.

Products Lineup : Distance Detection Based Sensors

The LR-X Series is a remarkably small laser sensor capable of detecting targets based on position and is unaffected by colour, surface finish, or shape. Impressive durability is achieved with its food-grade stainles steel housing (SUS316L), high IP ratings, and guarded cable. Position changes as small as 0.5 mm are possible, along with automatic and real-time intensity adjustment to ensure stable detection on any target.

Features

Compact & Robust Design for Use Anywhere

Whether building a new machine or retrofitting an older one, the ultra-compact size of the LR-X Series makes it easy to integrate into any space. The metal housing and rugged design also ensure it will last in any environment.

Stable Detection of Any Target

Minimum Detectable Position Change: 0.5 mm

The LR-X Series detects targets based on position, not light intensity. This allows for stable detection of targets regardless of colour, surface finish, or shape. This allows the LR-X Series to be used in a wide variety of applications, including those with small position changes.

Shiny Metals

Rounded Surfaces

Black/Dark Targets

Varied Colours

Angled Targets

The LR-T Series of reflective sensors represents a seamless fusion of innovative technology and robust functionality.

Features

Superior Detection Capabilities

The LR-T is designed to detect at long ranges while remaining highly stable. This is achieved due to the HS2 technology used, a combination of Time of Flight detection and a custom integrated circuit. Additionally, the interference prevention and Datum Function allow users to maximize this sensors capability in any situation.

Easy to Use

The LR-T Series is simple to install and calibrate. Flexible mounting options, a visible beam spot, push button teach, and an easy to read display allow for quick setup. Even at long distances, constant feedback is provided with the LR-T's highly visible status indicator.

Laser sensor capable of detecting targets based on both position and contrast (detectable distance: up to 500mm).

Features

Best Detection Ability in its Class

The LR-Z's unique U.C.D. Function allows for stable detection of clear, metallic, or dark targets. This series can also detect purely based on distance, regardless of shape, colour, or surface finish.

Durable & Long Life

The IP68/69K rating means the LR-Z is ready for the roughest of factory environments. Wash-down, oil spray, and many corrosives are no match for the stainless steel body. Additionally, physical impact or even overtightening are not a concern because of the highly durable design.

Simplified Operation

Simple setup and easy operation are at the core of the LR-Z's design. With a simple 1-touch teach, calibrating this sensor is straightforward and quick. A highly visible indicator and a 7-segment display make this sensor very easy to use.

New feature U.C.D. Function Distinguishing a Target From a Background Using the Distance and Received Light

The sensor first registers the distance to the background and the received light, which are used as reference, and then detects the target by sensing that the distance or received light differs from the registered reference when a target comes into the detection area. With the background, stable detection of target is ensured even if the target is a complex shaped object, has changes in colour and surface condition, or is a thin object with a small height difference.

Without Target

With Target

-

1Difference in distance

-

2Difference in received light

The NEW GV Series Digital CMOS Laser Sensor provides unmatched performance, even on metal and black (rubber) targets. Multiple models available to meet all your laser sensing needs.

Products Lineup : Received Light Based Laser Sensors

Using a laser enables long distance detection for difficult applications while maintaining a focused, visible beam spot.

Features

Long Range and Visible Beam Spot

LV-N models feature a visible beam spot and sensor options powerful enough to blast up to 26ft. These features offer increased mounting and detection flexibility all while being as safe as a photoeye.

Simplified 1-Touch Teach

Complete set up with just one click. This feature sets the bar when it comes to quick set up.

Choose from the largest selection of laser sensors in the industry!

Choose from the largest selection of laser sensors in the industry!

Products Lineup : Laser Displacement Sensors

IL Series CMOS multi-function analogue laser sensors are reflective laser displacement sensors that provide the best-in-class detection ability and stability at a reasonable cost. Stable detection is possible without tuning for workpiece types or their surface conditions, so the IL Series can be added to production lines to help make setup, changeover, and product changes easier. With a wide-ranging lineup of sensor heads, including high-accuracy models and long-range (up to 3.5 m) models, these laser sensors can be applied to diverse applications thanks to their broad dynamic range and environmental resistance. 1 μm repeatability allows for use in high-tolerance detection setups that previous sensors could not stably provide.

Features

Sharp-Line Sensor Heads

Introducing a new high-performance head for the IL Series Stable performance for the most demanding detection

Multi-Function Amplifier

The multi-function amplifier with an all-in-one design

Tough, Reliable, Repeatable Laser Measurement Simplified. KEYENCE brings you an economical analogue laser sensor.

A laser sensor uses a “laser” to emit light in a straight line. Its visible beam spot makes alignment and positioning very easy. Since the light beam is focused, the sensor can be installed without worries about stray light. The major types of laser sensors include reflective, thrubeam and retro-reflective.

Principles and major types of laser sensors

Laser sensors are largely divided into multi-purpose types and distance-setting types. Multi-purpose types are further divided into reflective, thrubeam and retro-reflective models. All of these models use a visible laser beam but their detection principles are different. This section describes these models and their detection principles with illustrations.

Multi-purpose laser sensor

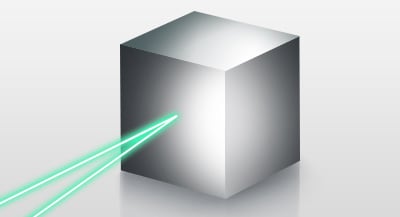

Reflective laser sensor:

The sensor head contains both a laser light emitting element and a light receiving element, so it is also called a transmitter/receiver. To detect targets, the sensor emits a laser beam to make it reflect from the surface of the target and receives the reflected beam to detect the target.

A: Transmitter/receiver (sensor head), B: Light emitting element, C: Target, D: Reflected light, E: Light receiving element

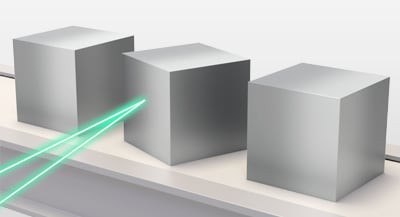

Thrubeam laser sensor:

The laser’s optical axis forms a signal beam between a transmitter containing a laser light emitting element and a receiver containing a light receiving element. The sensor detects targets by sensing whether the laser signal beam emitted from the transmitter is interrupted by the target or not.

A: Transmitter, B: Light emitting element, C: Signal beam, D: Target, E: Signal beam interrupted, F: Receiver, G: Light receiving element

Retro-reflective laser sensor:

A signal beam is formed between a transmitter/receiver (sensor head) and a reflector. When the signal beam is interrupted by a target, the light receiving element receives the light reflected by the surface of the target and detects the target.

A: Transmitter/receiver (sensor head), B: Light emitting element, C: Target, D: Reflector, E: Signal beam interrupted, F: Light receiving element

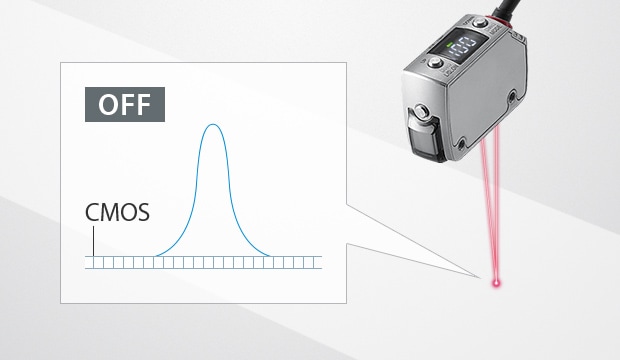

Distance-setting type laser sensor

This type of laser sensor contains a laser light emitting element, a receiver lens and a light receiving element (CMOS) in the sensor head. The sensor emits a laser beam to a target and receives the reflected light. Based on the change in the position where the light is received (light entry angle), the sensor can detect the change in the distance to the target (height or position of the target). When using this principle, the path of the laser beam from the light source to the point of reflection on the target surface to the light receiving element forms a triangle. Consequently, it is called the triangulation principle (method).

Left: Target is near, Right: Target is far

A: Laser light emitting element, B: Target surface, C: Reflected light, D: Light receiving element (CMOS)

Benefits of Laser Sensors

Unlike light from LEDs or other light sources, the light beam of a laser sensor is visible and travels in a straight line, so the position of the beam spot can be found immediately. Since the mounting position can be determined easily, the time needed for integration or changeover can be reduced greatly when compared with photoelectric sensors.

Unlike light from LEDs or other light sources, the laser beam emitted from a laser light emitting element travels in a straight line. Since the light is visible, the beam spot is easily identified. With a reflective laser sensor, it is possible to visualise whether or not the beam spot is exactly in the desired position. With a thrubeam laser sensor, installation can be done quickly and accurately because it is easy to align the optical axis and determine the detection position. This brings advantages such as reduced installation work and more precise installation.

The laser beam used for laser sensors not only travels in a straight line and has high power, but also does not spread over long distances. The sensor can maintain a small beam spot even for long distance detection, which can help meet various installation conditions.

Laser sensors emit powerful light that does not spread, even over long distances. This means detection is possible far from the sensor head. For example, even when the sensor needs to be mounted at a distance (robotic cells, operator interference, high temperatures, chemical splashing, etc.) the small beam spot allows for detection as desired. KEYENCE also provides a wide variety of sensor heads that can be used under various installation conditions, including types offering variable beam spot sizes and those specialised for long-distance detection.

By using a light beam from a laser light source that travels straighter than LEDs, laser sensors generate hardly any stray light. They have the advantage of fewer false detections even when installed in narrow spaces inside machines or equipment.

Sensors using LED light sources are susceptible to interference from stray light. When these sensors are installed in narrow spaces inside equipment, false detections may be caused by unexpected reflection. Laser beams do not generate stray light even in narrow spaces. They travel in straight lines to allow detection with small beam spots. It is also possible to install reflective laser sensors in spaces inside equipment to detect targets or to use thrubeam laser sensors to detect and monitor gaps themselves. KEYENCE offers a lineup that includes compact sensor heads that can be chosen based on installation conditions.

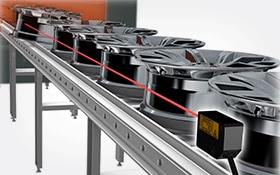

Laser Sensor Case Studies

Detecting remaining roll of transparent film

The remaining amount of film is detected with a laser beam applied to the side of the roll of film. For roll machines and automatic packaging machines, this ensures proper timing to feed the film (base material) and prevents problems. KEYENCE’s laser sensor (LR-ZH) has the U.C.D. (Universal Change Detection) function that can detect the remaining amount of transparent film. If there is no background, the roll can be detected in combination with a reflector.

Long-distance detection for web tension control

Introducing a position based laser sensor (laser displacement sensor) allows for consistent loop control during transfer of a sheet or web. KEYENCE offers a lineup of ultra-long range laser displacement sensors that can perform accurate detection even from distances up to 3500 mm (137.80"). This range offers flexible installation and ensures stable detection while staying out of harm's way.

The Sensor Basics website describes a variety of sensors that are useful in factories based on their principles. It introduces everything from basic knowledge such as types and mechanisms to troubleshooting and application examples.

Frequently Asked Questions About Laser Sensors

If ambient light, such as pulse-lighting inverter light or light from a fluorescent lamp, enters the receiver of a laser sensor, the sensor may incorrectly recognise it as reflection of the light it emitted. To prevent this problem, install a shield between the sensor’s receiver and the ambient light source so that the sensor does not receive the ambient light. Alternatively, adjust the angle of the receiver so that it does not receive the ambient light. Also provide as much distance between the ambient light source and receiver as possible. In some cases, using a direct-current lighting light source may reduce the chance of sensor malfunctions.

Transparent objects have high transmission ratios. It is not uncommon to see presence detection of transparent objects fail due to insufficient difference in the received light intensity. Sometimes a slight change in the received light intensity, such as the position of the reflector, can have a negative effect on detection. To solve this problem, mount the sensor so that the optical axis is angled toward the entry direction of the transparent object instead of perpendicular to the entry direction. This makes the shaded area larger and the receiver less likely to receive specular reflection from the target. This should result in a sufficient difference in received light intensity to detect the presence of the target. When using a retro-reflective model, selecting a model with a large spot size can reduce the variation in the amount of reflected light caused by the reflector position. If the detection requires identifying a subtle difference in light intensity, using a separate amplifier model to visualise the received light intensity will make it easier to determine the best settings on site. It can also help to use an amplifier that is capable of automatic correction of setting values.

Mirrored targets tend to cause specular reflection of light. When the tilt of the target changes, the laser beam traveling in a straight line may not return properly to the receiver, resulting in insufficient received light intensity. As a countermeasure, when using a reflective or distance-setting type laser sensor, intentionally detect the target in a slightly tilted position. Alternatively, if there is some part on the target other than the mirrored surface, aim the sensor at that part to make detection easier. If detection fails with a reflective or distance-setting model, use a thrubeam or retro-reflective laser sensor which is less affected by surface conditions. Selecting a model with a light beam that "spreads," such as a fibreoptic sensor, can reduce the variation in the received light intensity when a mirrored target is tilted.

![LASER SOLUTIONS [AUTOMOTIVE EDITION]](/img/asset/AS_65633_L.jpg)