Positioning Sensors

These easy-to-use sensors can be used in a large variety of diverse applications such as highly accurate positioning and product type difference checking.

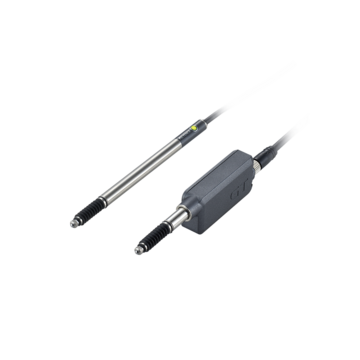

Products Lineup : Contact Positioning Sensors

The Scale Shot System in the GT2 Series improves upon the technology of conventional contact sensors and is now concentrated into a pencil-type sensor head.

Features

IP67G Oil-Resistant Design for Measurement in Machine Processing and Other Oily Environments

The sensor head - including the connector and cable section - are IP67G and NEMA Type 13 compliant. This means that stable measurement is achieved even in harsh environments containing splashing water or oil. In order to improve robustness - a common problem with contact sensors - careful attention was paid to the structure of the sensor body. The design incorporates a high-strength linear ball bearing and a seamless body for additional durability. In addition, the reduced weight of the spindle means minimal wear from friction and significantly improved durability. These design improvements reduce maintenance and equipment downtime.

Disc assembly inspection

Choose from 29 Different Head Variations

The GT2 Series is available in a wide range of heads, including pencil, air, and low-speed pressure types. Choose a design most suitable for the application.

Tough and rugged general purpose digital contact sensor with push button calibration.

Products Lineup : Reflective Positioning Sensors

IL Series CMOS multi-function analogue laser sensors are reflective laser displacement sensors that provide the best-in-class detection ability and stability at a reasonable cost. Stable detection is possible without tuning for workpiece types or their surface conditions, so the IL Series can be added to production lines to help make setup, changeover, and product changes easier. With a wide-ranging lineup of sensor heads, including high-accuracy models and long-range (up to 3.5 m) models, these laser sensors can be applied to diverse applications thanks to their broad dynamic range and environmental resistance. 1 μm repeatability allows for use in high-tolerance detection setups that previous sensors could not stably provide.

Features

Sharp-Line Sensor Heads

Introducing a new high-performance head for the IL Series Stable performance for the most demanding detection

Multi-Function Amplifier

The multi-function amplifier with an all-in-one design

Tough, Reliable, Repeatable Laser Measurement Simplified. KEYENCE brings you an economical analogue laser sensor.

Products Lineup : Thrubeam positioning sensors

The intelligent I-Series consists of a high-accuracy sensor lineup that offers high cost-performance with the most advanced functions for on-site operations.

Features

Easy to Use

The position monitor makes it easier to align the optical axis. Easily perform optical axis alignment by adjusting the sensor head so that all of the position monitor lights turn red.

Environmental Resistance

The enclosure satisfies the IP67 rating based on the IEC standards and remains watertight even after being held at a depth of one meter for 30 minutes. The enclosure is resistant to adverse environments and offers long-term durability.

The intelligent I-Series consists of a high-accuracy sensor lineup that realises low-cost high performance with only the most advanced functions for on-site operations.

Positioning sensors identify positions by detecting the target’s distance, height, width and other information. Different sensors can be selected according to the workpiece shape, conditions and application.

Contact-type displacement sensors that operate on the typical principle of linear variable differential transformers (LVDT) detect and measure the changes in the height of the target by capturing the mechanical linear movement of the probe as displacement. For non-contact displacement sensors, laser displacement sensors are the most common among optical types due to the linearity of the light. Laser displacement sensors can be further classified into reflective and thrubeam models. Reflective models detect the position and height based on the distance from the target. Thrubeam laser displacement sensors can continuously detect not only the position of objects passing vertically through the band of signal light, but also their outer and inner diameters.

Types and working principle of positioning sensors

Sensors used for positioning workpieces can be selectively applied according to the workpiece shape and detection conditions. Detection methods are broadly categorised into two groups: contact and non-contact. Contact displacement sensors (touch sensors) that bring a probe into direct contact with a target are typical contact-type positioning sensor. Laser displacement sensors are a typical example of non-contact positioning sensors, using the linearity of laser light for detection. The following section explains the types and working principles of these typical positioning sensors.

Contact-type positioning sensors

Linear variable differential transformer (LVDT) method:

An LVDT displacement sensor detects mechanical linear movement as displacement and converts it to an electrical signal.

This type of sensor has a core at its centre with coils located around it. A probe is attached to the tip of the core to make up a spindle. The spindle is pushed against the target with a spring mechanism, sliding along with the changes in the target’s height. A magnetic field is generated when current passes through the coil, moving the core inside. The resistance of the coil and the output signal level change according to the amount of core movement. The movement of the core shows changes in the shape of the target, which means displacement can be measured from the changes in the output signal level. These changes can be used for height measurement and positioning.

Scale (pulse count) method:

Contact displacement sensors using the scale method are also called pulse-count sensors.

The vertical movement of the spindle caused by it coming into contact with the target is converted by an internal scale into signals to detect the position. Pulse counting comes in two types: magnetic pulse counting, which counts pulses using an S(N)-pole magnetic field; and optical pulse counting, which counts pulses using a light receiving element with slits on the scale as a light source.

The detection accuracy of the scale method depends on the accuracy of the built-in scale.

KEYENCE developed the Scale Shot System II, the world’s first system that uses a CMOS sensor for high-speed scanning of an absolute value glass scale that incorporates slits with complex patterns that vary depending on the position. This allows the sensor to measure height (position) with precision, obtain the absolute position and detect position information, which means it does not need zero point adjustment. These properties also offer other advantages, such as protection against tracking errors and good temperature characteristics.

However, contact-type positioning sensors are not suitable for use with soft workpieces that can be deformed by the probe and workpieces that are prone to scratching.

Non-contact positioning sensors

Reflective laser displacement sensors:

One sensor head emits laser light on the target, and the reflected light is received by the built-in light receiving element (e.g. CMOS). This type of sensor can capture the distance to the target based on the changes in the position of the reflected light received by the CMOS through the receiver lens and detect the position and height. This principle is called the triangulation method because the laser’s path is a triangle.

Laser displacement sensors that use a CMOS as the light receiving element can provide high-accuracy position detection.

Thrubeam laser displacement sensors:

This type of sensor creates a band of laser signal light between the laser transmitter and the receiver. When a target passes through the signal light, part of the signal light is blocked. The changes in the amount and position of laser light coming through are captured by the light receiving element (e.g. CCD) to detect the target without coming into contact with it.

The width of the band of the laser varies, which allows use in a variety of applications, such as target position and edge detection as well as clearance and inner/outer diameter measurement, regardless of the workpiece shape or purpose.

Laser displacement sensors can not only position targets without touching them, but also support a wide range of applications by placing multiple sensor heads according to the workpiece shape or purpose. Multiple reflective models can be placed targeting flat workpieces from different directions to measure their flatness based on height differences. Thrubeam models can detect the outer and inner diameters of objects.

Benefits of Positioning Sensors

Compared to other positioning sensors, laser displacement sensors can detect and differentiate targets of any material due to their non-contact operation. Their flexibility in installation also means that they support a variety of applications, including positioning a diverse range of workpiece shapes and sizes as well as detecting heights and outer/inner diameters.

Laser displacement sensors are generally unaffected by the target’s surface conditions, allowing their use with various workpieces. Another notable advantage is their freedom of installation. Thanks to the linearity of laser light, these sensors can be flexibly installed without concerns about detecting distance. Also, laser light does not diffuse, so these sensors can target narrow clearances while preventing scattered light effects. Environment-resistant sensor heads can withstand use in high-temperature conditions while high-power type thrubeam laser displacement sensors have much lower false detection rates even in the presence of some dust.

Compared to other positioning sensors, laser displacement sensors can continuously detect and differentiate positions without stopping the targets. Therefore, they do not compromise the cycle time of production lines or scratch surfaces or otherwise damage workpieces thanks to their non-contact detection.

Unlike vision sensors, laser displacement sensors do not need shutter releases, and therefore they can continuously detect the edges of moving workpieces. Thrubeam models can continuously detect the outer diameter of extruded bar-shaped workpieces or the entire length of an edge of a sheet or film on a roller machine. Other possible applications include run-out detection. As both reflective and thrubeam types do not need to come into contact with targets, they can detect soft-material workpieces without affecting their shapes. They are also effective for use with delicate, easily-scratched targets.

Some sensor heads for positioning sensors provide micron-order beam spots, which enable detection of tiny areas on small workpieces. Sensors using a red light laser can be easily installed by looking at the beam spot while adjusting the detection position.

Compared to other positioning sensors, laser displacement sensors can accurately detect tiny areas on small targets (for example, approximately 200 × 750 μm at the reference distance for the IL-030), which is difficult with contact-type displacement sensors. Because laser light has better linearity compared to LEDs, these sensors are capable of accurately detecting deep, narrow areas from a distance. This allows laser displacement sensors to help significantly reduce installation time and effort compared to photoelectric sensors. A laser displacement sensor with red laser light can be useful when checking whether the beam is hitting the intended spot.

Positioning Sensor Case Studies

Edge position detection during film transfer

Workpieces meandering during transfer is a cause of wrinkles and slacks in films and other thin products. Continuing to wind the workpiece with the edge position misaligned can cause slacks due to uneven roll winding, resulting in the workpiece meandering. This produces defective rolls and reduces yield. IG Series multi-purpose CCD laser micrometres provide continuous, high-precision differentiation of the edge positions of workpieces in motion. The newly developed optical system enables stable edge detection and monitoring of thin, transparent and meshed films and sheets. The detected film transfer status is also provided to the system as feedback, which allows for edge control.

Measurement and differentiation of product dimensions and outer diameter

If you want to prevent workpieces sustaining scratches or other damage from contact-type measuring instruments, you should consider non-contact measurement using a vision system. However, if your purpose of measurement is limited to the workpieces’ thickness, width, height and/or warpage, a vision system is too costly to introduce and too complicated to operate considering the application. IL Series CMOS multi-function analogue laser sensors can detect targets of any colour or material at reasonable cost. By measuring displacement at multiple points, the IL Series can detect workpiece shape and warpage as well as measure the thickness and width of extruded products.

Depending on type, positioning sensors have different precautions and necessary actions when installing and using them. The following section explains the key points for installing and using each common type of positioning sensor.

Contact-type displacement sensors

Contact-type displacement sensors touch targets directly with a probe to detect their positions by calculating the changes in the spindle height. To ensure that a contact-type displacement sensor stably detects targets inline, you must take the following precautions during installation and use.

During installation

The sensor must be installed with the correct angle in relation to the direction of position detection, and this angle must be maintained. In general, contact-type displacement sensors have a small measurement point. This means that once the angle in relation to the direction of detection shifts, the angle of probe contact shifts as well, which may result in errors.

Maintaining accuracy and stability

While contact-type displacement sensors have an advantage in repeatability, measurement errors can occur if the sensor itself moves out of place. The sensor must be firmly secured with a jig so that no change can occur to the angle and measuring distance during repeated measurements.

In the case of conventional sensors using the scale (pulse count) method, if the spindle moves abruptly due to vibration or other reasons, the response of the photoelectric sensor may be delayed, resulting in tracking errors. You will need to take measures against significant vibrations caused by any machines in the vicinity when installing these sensors.

Reflective laser displacement sensors

Reflective laser displacement sensors detect the position (distance) of targets at points. Therefore, single or multiple reflective laser displacement sensors can be used for a diverse range of applications. The type and number of sensor heads should be selected depending on the required detecting distance and accuracy, as well as installation location. The following section introduces typical applications and key points when considering the characteristics of their triangulation principle of detection.

During installation

In order to correctly receive the reflection of the emitted laser, the laser is emitted vertically from above the target. Depending on the sensor head selection and installation, the sensor may be installed at an angle. If necessary, consider the option of selecting a sensor head that can be installed at an angle.

Differences in target material and colour

Significant differences in the material or colour of the surface of targets can increase the rate of measurement errors. In general, measurement errors can be minimised by installing the sensor such that the line connecting the laser beam axis and the light-receiving axis of the light reflected from the target is parallel to the target’s borderline.

KEYENCE’s IL Series reflective laser displacement sensors can provide stable detection without tuning thanks to automatic adjustment of laser power, shutter time and reception gain (amplification factor) in response to changes in target colour and surface conditions.

Detection of concavities and narrow parts such as grooves in workpieces

If the part that you want to detect is surrounded by deep concavities or grooves, detection will not be possible if either the laser beam axis or the light receiving axis is blocked by an inner wall. When installing the sensor, you make sure that the light paths are not blocked, taking measures such as reviewing the detection points, installing a sensor head with a long detecting distance, or making the angle between the laser beam axis and light receiving axis smaller.

KEYENCE offers a sensor lineup that includes an ultra-long range sensor head that has a detecting distance of up to 3500 mm (137.80").

Thrubeam laser displacement sensors

Thrubeam laser displacement sensors produce a band of laser light on the light emission and receiving sides, and detect targets passing through based on how much light the target transmits. The width of the laser light of a thrubeam laser displacement sensor is determined based on detection requirements and the shape and size of the workpieces. The key points for installation and use are described below.

During installation

Correct alignment of light emission and receiving axes is critical for detecting targets. When installing the sensor, make sure the axes do not move even in the presence of any vibrations caused by nearby equipment. The axes should also be periodically checked to prevent errors.

Considering the ease of installation and use, it is important to select a laser displacement sensor that allows for easy inspection of the beam axis. KEYENCE’s thrubeam laser displacement sensors allow you to easily visualise the optical axis with an LED provided in the main unit. This facilitates optical-axis alignment during installation and changeovers.

Positional relationship with the target

When detecting the outer diameter of a bar-like or cylindrical workpiece, set up the sensor so that the band of laser light is vertically perpendicular to the longitudinal side of the workpiece. If the angle of the laser band is incorrect, an error will occur in the detection of outer diameter.

The Sensor Basics website introduces the working principles of nine different sensor types, their characteristics and application examples, covering fibreoptic sensors, photoelectric sensors, vision sensors and other essential sensors for modern factory automation, which includes, of course, laser displacement sensors and other laser sensors.

Frequently Asked Questions About Positioning Sensors

In most cases, optical-axis alignment is more difficult as the distance increases. Additionally, the optical axis can shift when the sensor is installed and used in a location where there is significant vibration. Alignment problems may occur, so periodic inspections are necessary. In consideration of this issue, KEYENCE’s thrubeam laser displacement sensors allow you to visualise the optical axis with an LED on the sensor. IG Series multi-purpose CCD laser micrometres have a position monitor in the main unit, and IB Series thrubeam type laser detection sensors have an alignment LED in the main unit, both of which indicate the position of the laser beam axis in a visible manner. You can directly see the state of the beam axis, which facilitates smooth setup and adjustment.

The IL Series sensor lineup includes an ultra-long range model, which can be installed up to 3500 mm (137.80") away from the surface of the target. For example, this laser sensor can detect sheet height in the clearance of a rolling machine without interfering with the machine. Hoop control during transfer of sheets or other workpieces is possible by providing the detected data as feedback to the machine. This model also supports applications in hot temperature environments, such as steel plate thickness measurement in high-temperature conditions, dimensional measurement of hot forgings and positioning of robots that handle hot products.

![Error-free Displacement Measurement: Reflective Laser Displacement Sensors [Installation Guidelines]](/img/asset/AS_102767_L.jpg)