- Home

- Solutions

- Case Studies

- KEYENCE VHX-7000 Optimises Safety and Quality for leading Medical Manufacturer

KEYENCE VHX-7000 Optimises Safety and Quality for leading Medical Manufacturer

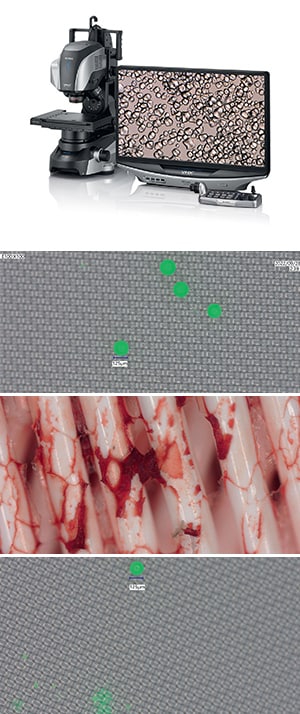

The versatility and accuracy of the KEYENCE VHX-7000 all-in-one digital microscope is seeing it play a vital role in optimising both patient safety and production quality for a leading UK manufacturer of medical systems.

Based in Worksop in Nottinghamshire, Chalice Medical Ltd is the only UK-based specialist manufacturer of membrane oxygenators. The company has used conventional microscopes for various inspection tasks but decided to invest in the VHX-7000 for its high magnification and accuracy which would help ensure Chalice Medical kept pace with intensifying requirements around quality and safety. As well as its ease of use – alignment and focus are undertaken automatically – and ability to rapidly generate and store both two- and three-dimensional images, Chalice Medical were attracted by the VHX-7000’s compact footprint and the aftersales service and support available from KEYENCE.

Chalice Medical’s products literally provide a lifeline for patients either suffering from severe lung conditions or awaiting cardiac surgery in hospital critical care units. The company’s offering extends to the manufacture of tubing packs, blood pumps and mini heater coolers, all of which see service within critical care units and operating theatres around the world. Manufacture of this product type is governed by highly stringent local and international regulation given their use in the care of highly vulnerable patients.

In particular, both BSI and ISO regulations set very strict standards when it comes to the ability of these products to prevent the ingress of particles above a certain size into the bloodstream of a patient. This means there can be no compromise in the selection and performance of filtration systems, with filters typically selected for these applications able to remove particles between 40 µm to 200 µm in diameter.

These filtration systems require extensive testing before any product can leave the Chalice Medical facility and this is where the VHX-7000 has proved invaluable. Particles slightly wider than the filter pore size are added into sterile water which is then passed through the filter. The filtered fluid is then collected and fed through a 30 µm filter disk. Any particles which pass through the larger filter should, in theory, be collected by the smaller diameter filter disk. To verify that this has happened, the filter disk is dried and placed under the VHX-7000 to check for particle passage.

However, this is far from being the only application for the VHX-7000 within Chalice Medical. Its employment actually begins far earlier in the manufacturing process.

In the medical sector, manufacturing quality simply cannot be compromised. It is critical that any plastic parts are free from defects, scratches and also the plastic injection pin indentations which can cause severe damage to red blood cells.

This means detailed inspection of these components is critical. The Chalice Medical team discovered that using the VHX-7000 microscope is not just quicker and easier to use than a conventional microscope, but more accurate too as it can assist in identifying the source of any quality issues in production.

Of particular benefit here is the VHX-7000’s ability to produce three-dimensional images of similar quality to a scanning electron microscope through its 4K CMOS image sensor with multidirectional lighting variation technique. This provides the most detailed image and allows accurate calculation of depth.

This is a feature that has enabled Chalice Medical to establish whether imperfections are being caused by manufacturing issues, handling issues or simply human error. Indeed, the ability of the VHX-7000 to quickly take detailed images and generate and share reports has been central in providing an overall picture of manufacturing quality within Chalice Medical, resulting in substantial cost savings.

Successful performance of these varied tasks is only possible thanks to the VHX-7000’s unique combination of optics, digital camera, electronics, software, and a wide choice of motorised XYZ and rotary stages, meaning it is ideally suited to meeting Chalice Medical’s evolving needs as its product offering continues to develop.

APPLICABLE PRODUCT CATALOGUE