Examples of countermeasures in the plastics industry

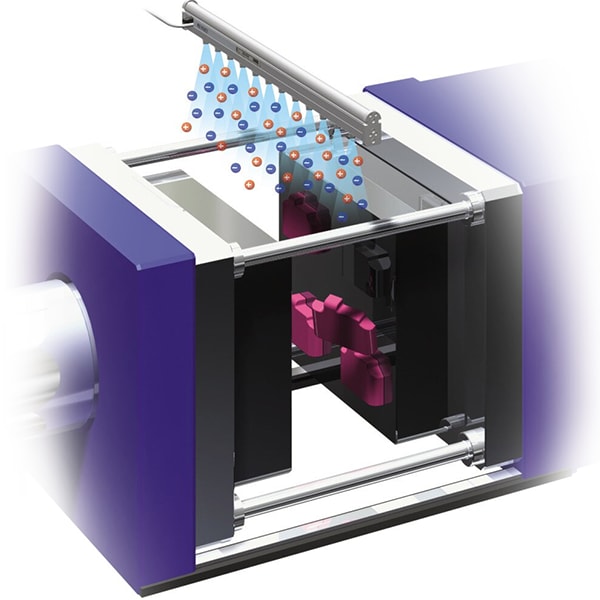

Foreign particle removal before coating

- Adhesion of foreign particles

- Staff discomfort

Utilising static elimination with a large air flow makes it possible to remove foreign particles adhered to targets even without a factory air supply.

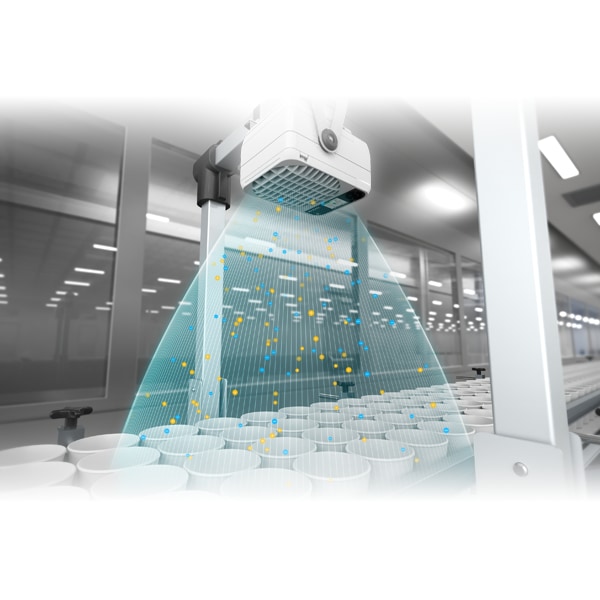

Preventing foreign particles from adhering to food containers

- Adhesion of foreign particles

Just one ionizer can be used to eliminate static electricity quickly over a wide area. Constantly monitoring the level of electrostatic charge, which strongly influences the adherence of foreign particles, makes it possible to improve yield rates.

Preventing adhesion of parts to moulds and adhesion of foreign particles

- Adhesion of foreign particles

Strong electrostatic charges can be generated during injection moulding. Products become defective when foreign particles adhere to them due to static electricity. These products must be disposed of. Static electricity can also cause products to stick to moulds. These products must be removed by hand, which reduces the yield. An ionizer can prevent adhesion of foreign particles and ensure that products do not stick to the mould.

Preventing jamming in part feeders

- Clogging, sticking, splashing

Static electricity can cause parts to jam in the part feeder, resulting in feeding errors. An ionizer can eliminate this problem.

Eliminating static charge during roll-to-roll loading

- Clogging, sticking, splashing

- Adhesion of foreign particles

- Staff discomfort

Very strong electrostatic charges occur during roll-to-roll loading. This static electricity can potentially cause problems including inability to pull off the wrapping film, staff feeling pain, sparks occurring during unwinding, or foreign particles getting stuck during wrapping. The latest ionizers from KEYENCE can eliminate these problems.

Preventing re-adhesion of plastic chips to products after processing

- Adhesion of foreign particles

When a plastic part is cut or polished, waste material from this process remains attached to the part. To avoid damage, this waste must be blown off – an air-supplied ionizer can do just that.

For more information, please contact KEYENCE.