Examples of countermeasures for foreign particle adhesion

Foreign particle removal before coating

Utilising static elimination with a large air flow makes it possible to remove foreign particles adhered to targets even without a factory air supply.

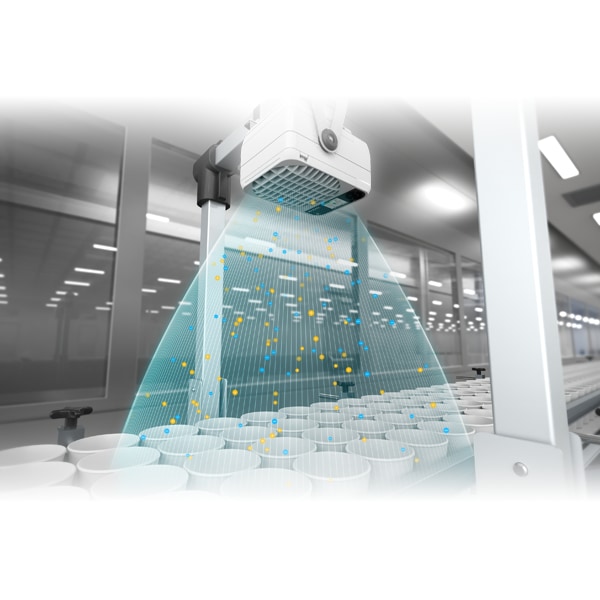

Preventing foreign particles from adhering to food containers

Just one ionizer can be used to eliminate static electricity quickly over a wide area. Constantly monitoring the level of electrostatic charge, which strongly influences the adherence of foreign particles, makes it possible to improve yield rates.

Preventing adhesion of trim waste

When a plastic part, such as an instrument panel, is cut, waste material from this process remains attached to the part. To avoid potential damage, this waste must be blown off – an air-supplied ionizer can do just that.

Eliminating static charge during bumper coating

After a bumper is cast, foreign particles can adhere to it when it is transported to the coating process. Wiping bumpers so that they are clean enough to meet coating quality standards is time-consuming and laborious. In the worst-case scenario, bumpers may even have to be disposed of as a result of foreign particles. This problem can be avoided with an ionizer.

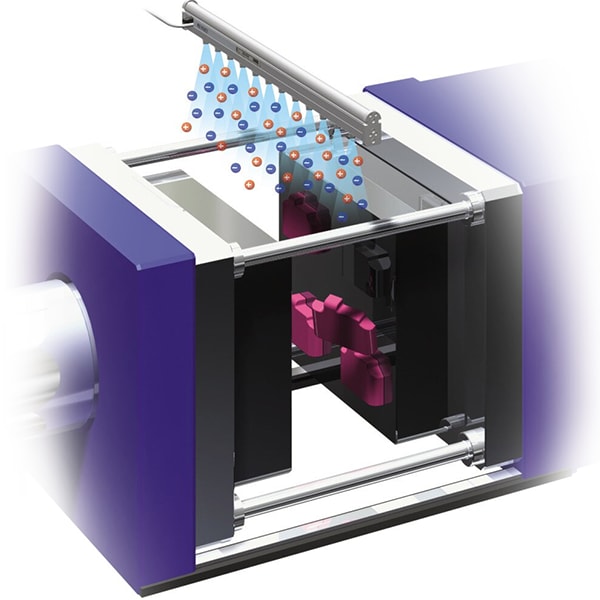

Eliminating static charge during coating

In order to coat the paper with a silicone layer, a very strong electrostatic charge (50 to 100 kV) is generated in the sticker release paper, which can lead to problems such as adhesion of foreign particles, sparking and staff discomfort. An ionizer can eliminate these problems.

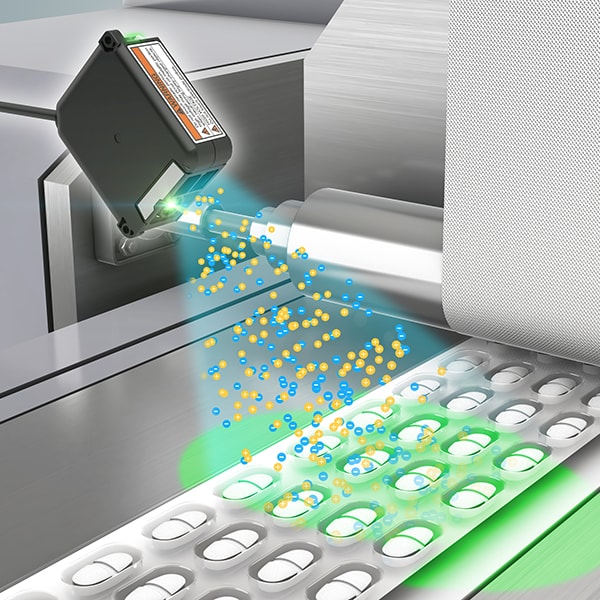

Preventing defects on blister packs

A strong electrostatic charge on the blister packaging film can result in foreign particles adhering to it and cause the contents of the packaging to be misplaced or cracked. An ionizer can reduce these errors.

Preventing foreign particles from adhering to containers

The faster the line speed, the greater the electrostatic charge. Because of this increased charge, more foreign particles remain stuck inside containers, which can result in more products failing quality tests, more inspections having to be repeated, and more complaints from customers. An ionizer can prevent adhesion of foreign particles.

Preventing ESD during the transport of PCBs

During transport, PCBs become statically charged due to contact and separation from conveyor belts. Strong charges can lead to electrostatic destruction and adhesion of foreign particles, which in turn can lead to manufacturing defects. An ionizer can reduce these defects by eliminating the electrostatic charge.

Preventing electrostatic destruction of electronic PCB testers

A foreign object between the probe and the PCB during conductivity testing is considered a conductivity defect and means the test has to be repeated, greatly reducing the yield. Sensitive probes can even be damaged by the static electricity. An ionizer can eliminate these problems.

Removing foreign particles during camera assembly

Parts become statically charged due to friction and debonding during assembly. Countermeasures are required for this charge, as it can introduce foreign particles into the parts, resulting in noise in the images. An ionizer can prevent adhesion of foreign particles.

Preventing adhesion of parts to moulds and adhesion of foreign particles

Strong electrostatic charges can be generated during injection moulding. Products become defective when foreign particles adhere to them due to static electricity. These products must be disposed of. Static electricity can also cause products to stick to moulds. These products must be removed by hand, which reduces the yield. An ionizer can prevent adhesion of foreign particles and ensure that products do not stick to the mould.

For more information, please contact KEYENCE.